A indústria automotiva está à beira de uma transformação revolucionária, na qual os princípios tradicionais de fabricação se integram perfeitamente à tecnologia avançada de veículos elétricos. Essa convergência representa mais do que um simples avanço tecnológico; ela incorpora uma reimaginação completa da forma como abordamos soluções de transporte sustentável. As instalações modernas de manufatura automotiva evoluíram para ecossistemas sofisticados que priorizam tanto o apelo estético quanto a excelência funcional, criando ambientes onde a inovação prospera lado a lado com a eficiência industrial.

Os modernos centros de produção automotiva exibem uma impressionante combinação de sofisticação arquitetônica e domínio tecnológico. Essas instalações são testemunhos da engenhosidade humana, onde cada elemento de design cumpre tanto funções práticas quanto inspiradoras. A integração de processos de fabricação sustentáveis com um design industrial visualmente marcante cria espaços que não apenas produzem veículos excepcionais, mas também inspiram confiança no futuro da tecnologia de transporte.

Filosofia de Design Revolucionária na Fabricação Automotiva Moderna

Excelência Arquitetônica Encontra Design Funcional

A abordagem contemporânea para o projeto de instalações de manufatura automotiva representa uma mudança de paradigma em relação à arquitetura industrial tradicional. Centros modernos de produção automotiva adotam linhas limpas, fachadas extensas de vidro e layouts de conceito aberto que promovem tanto a eficiência operacional quanto o apelo visual. Essas escolhas arquitetônicas refletem uma compreensão mais profunda de como os ambientes físicos impactam produtividade, inovação e satisfação dos trabalhadores.

Sistemas estratégicos de iluminação iluminam as linhas de produção ao mesmo tempo em que criam efeitos visuais dramáticos que destacam a precisão e a arte da montagem moderna de veículos. A integração de elementos naturais, como paredes verdes e claraboias, cria ambientes que parecem mais laboratórios de inovação do que fábricas convencionais. Essa abordagem demonstra como a estética industrial pode elevar toda a experiência de manufatura, mantendo os mais altos padrões de excelência operacional.

Integração Tecnológica e Otimização Espacial

As tecnologias de edifícios inteligentes desempenham um papel fundamental na otimização dos aspectos estéticos e funcionais das instalações modernas de fabricação automotiva. Sistemas avançados de controle climático mantêm condições ideais de trabalho enquanto minimizam o consumo de energia, contribuindo tanto para o conforto dos trabalhadores quanto para os objetivos de sustentabilidade ambiental. Sistemas de integração digital permitem o monitoramento e ajuste em tempo real da iluminação, temperatura e qualidade do ar em toda a instalação.

O posicionamento estratégico de sistemas robóticos e equipamentos automatizados cria sequências de produção coreografadas que são tão visualmente envolventes quanto funcionalmente eficientes. Esses processos de fabricação cuidadosamente orquestrados demonstram como a tecnologia pode aumentar tanto a produtividade quanto a experiência estética geral dos ambientes industriais.

Práticas de Manufatura Sustentável e Inovação Ambiental

Implementação de Tecnologia Verde

A sustentabilidade ambiental tornou-se um pilar fundamental da fabricação moderna de automóveis, com instalações incorporando sistemas de energia renovável, tecnologias de redução de resíduos e processos de manufatura em ciclo fechado. Instalações com painéis solares e sistemas de energia eólica fornecem energia limpa para as operações de produção, enquanto sistemas avançados de filtração e reciclagem minimizam o impacto ambiental. Essas tecnologias verdes são integradas perfeitamente aos projetos das instalações, criando instalações visualmente impressionantes que cumprem tanto funções práticas quanto simbólicas.

Sistemas de conservação de água e iniciativas de zero resíduo demonstram como a responsabilidade ambiental pode ser alcançada sem comprometer o apelo estético ou a eficiência operacional. Sistemas de captação de chuva, reutilização de águas cinzas e instalações avançadas de tratamento são projetados como elementos arquitetônicos que realçam, em vez de prejudicar, a estética geral da instalação.

Inovação em Materiais e Princípios da Economia Circular

A implementação dos princípios da economia circular na fabricação automotiva cria oportunidades tanto para inovação ambiental quanto para aprimoramento estético. Sistemas avançados de recuperação de materiais permitem a reutilização e reciclagem dos materiais de produção, reduzindo resíduos ao mesmo tempo em que criam exibições visuais interessantes do processo de fabricação. Esses sistemas frequentemente incluem elementos transparentes que permitem aos visitantes e trabalhadores observar o fluxo circular de materiais por toda a instalação.

As escolhas sustentáveis de materiais estendem-se além dos insumos de produção para incluir materiais de construção e manutenção das instalações. Aço reciclado, madeira recuperada e compósitos ecológicos são utilizados ao longo da construção das instalações, criando elementos estéticos únicos que contam a história da responsabilidade ambiental e da inovação.

Tecnologias Avançadas de Fabricação e Excelência na Produção

Engenharia de Precisão e Controle de Qualidade

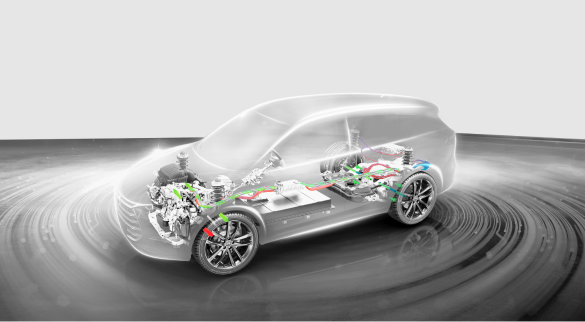

Instalações modernas de fabricação automotiva empregam tecnologias de engenharia de precisão de última geração que garantem uma qualidade excepcional de construção, ao mesmo tempo que criam ambientes de produção visualmente impressionantes. Centros de usinagem controlados por computador, sistemas de soldagem a laser e equipamentos de inspeção automatizados operam com precisão matemática, criando sequências de produção que são altamente eficientes e agradáveis de observar.

Os sistemas de controle de qualidade integram-se perfeitamente aos fluxos de produção, utilizando sensores avançados e tecnologias de imagem para monitorar todos os aspectos da montagem do veículo. Esses sistemas frequentemente apresentam exibições visuais impactantes que comunicam métricas de qualidade em tempo real, criando ambientes ricos em informações que apoiam tanto a excelência operacional quanto o envolvimento de visitantes.

Integração de Robótica e Automação

A integração de robótica avançada e sistemas de automação cria ambientes de produção que demonstram o futuro da tecnologia de manufatura. Robôs colaborativos trabalham lado a lado com técnicos humanos, realizando tarefas de precisão enquanto mantêm operações seguras e eficientes. Esses sistemas robóticos são frequentemente projetados levando em consideração aspectos estéticos, apresentando perfis elegantes e movimentos coordenados que criam sequências de produção visualmente envolventes.

Veículos autoguiados e sistemas de esteiras transportam materiais e componentes por toda a instalação com precisão coreografada, criando elementos visuais dinâmicos que demonstram a sofisticação da logística moderna de manufatura. Esses sistemas são projetados para operar silenciosamente e com eficiência, contribuindo ao mesmo tempo para o apelo estético geral do ambiente de produção.

Centros de Inovação e Instalações de Pesquisa

Estúdios de Design e Espaços Criativos

Instalações automotivas contemporâneas frequentemente incluem estúdios de design e centros de inovação dedicados que funcionam como hubs criativos para o desenvolvimento de veículos e avanços tecnológicos. Esses espaços possuem layouts flexíveis, tecnologias avançadas de visualização e ambientes de trabalho colaborativos que apoiam tanto a criatividade individual quanto a inovação em equipe. O design desses espaços enfatiza a iluminação natural, mobiliário confortável e elementos visuais inspiradores que estimulam o pensamento criativo.

Sistemas de realidade virtual e tecnologias avançadas de modelagem permitem que designers e engenheiros visualizem e testem novos conceitos em ambientes digitais imersivos. Essas tecnologias são frequentemente integradas em instalações visualmente impactantes que cumprem funções tanto funcionais quanto demonstrativas, destacando as capacidades de ponta dos processos modernos de desenvolvimento automotivo.

Laboratórios de Testes e Validação

Instalações abrangentes de testes nos centros de manufatura automotiva garantem que veículos elétricos atendem aos mais altos padrões de segurança, desempenho e confiabilidade. Esses laboratórios possuem equipamentos sofisticados para testes de baterias, análise de durabilidade e validação de desempenho, tudo instalado em espaços arquitetonicamente impressionantes que demonstram o compromisso com a excelência na engenharia automotiva.

Câmaras de testes climatizados, instalações de compatibilidade eletromagnética e instalações de testes de colisão são projetadas com funcionalidade e impacto visual em mente. Esses espaços frequentemente incluem áreas de observação e displays interativos que permitem aos visitantes compreender os rigorosos processos de teste que garantem a qualidade e segurança dos veículos.

Desenvolvimento da Força de Trabalho e Programas de Treinamento

Parcerias Educacionais e Desenvolvimento de Habilidades

As instalações modernas de fabricação automotiva frequentemente incluem centros abrangentes de treinamento que apoiam o desenvolvimento da força de trabalho e iniciativas de aprendizagem contínua. Esses espaços educacionais possuem equipamentos práticos para treinamento, sistemas de simulação e ambientes de sala de aula que preparam os trabalhadores para as demandas em constante evolução da fabricação automotiva. O design desses espaços enfatiza acessibilidade, integração tecnológica e princípios de aprendizagem colaborativa.

Parcerias com instituições educacionais e escolas técnicas criam caminhos para novos talentos ingressarem na indústria automotiva, ao mesmo tempo em que garantem que os trabalhadores existentes possam se adaptar às mudanças nas exigências tecnológicas. Esses programas frequentemente oferecem oportunidades de aprendizagem, programas de certificação e iniciativas de educação continuada que apoiam tanto o desenvolvimento profissional individual quanto o avanço da indústria.

Treinamento e Certificação em Segurança

Programas abrangentes de treinamento em segurança garantem que todo o pessoal da instalação entenda e implemente as melhores práticas para a segurança no trabalho e proteção ambiental. Esses programas utilizam sistemas interativos de treinamento, simulações de realidade virtual e exercícios práticos para comunicar eficazmente os protocolos de segurança. As instalações de treinamento são projetadas para replicar condições reais de trabalho, ao mesmo tempo que oferecem ambientes seguros para o desenvolvimento e prática de habilidades.

Programas contínuos de certificação garantem que os trabalhadores mantenham o conhecimento atualizado sobre requisitos de segurança, operação de equipamentos e procedimentos de emergência. Esses programas contribuem para a criação de ambientes de trabalho mais seguros e eficientes, ao mesmo tempo que apoiam o desenvolvimento profissional individual e oportunidades de progresso na carreira.

Perguntas Frequentes

O que torna as instalações modernas de manufatura automotiva diferentes das fábricas tradicionais?

As instalações modernas de fabricação automotiva integram tecnologias avançadas, práticas sustentáveis e princípios de design estético para criar ambientes que priorizam tanto a excelência operacional quanto o apelo visual. Essas instalações apresentam linhas arquitetônicas limpas, iluminação natural abundante e equipamentos de última geração que criam ambientes de trabalho inspiradores, ao mesmo tempo em que mantêm os mais altos padrões de eficiência e qualidade.

Como as práticas de sustentabilidade ambiental impactam o projeto e a operação das instalações?

As iniciativas de sustentabilidade ambiental são integradas perfeitamente ao projeto das instalações por meio de sistemas de energia renovável, tecnologias de redução de resíduos e princípios da economia circular. Essas tecnologias verdes muitas vezes funcionam como elementos arquitetônicos que realçam o apelo visual das instalações, ao mesmo tempo em que demonstram o compromisso com a gestão ambiental e práticas responsáveis de fabricação.

Qual é o papel da tecnologia na estética da fabricação automotiva moderna?

Tecnologias avançadas, como robótica, sistemas de automação e integração digital, criam ambientes de produção visualmente atraentes que demonstram a sofisticação dos processos modernos de manufatura. Essas tecnologias são projetadas com considerações estéticas em mente, apresentando movimentos coordenados, perfis elegantes e iluminação dramática que transformam processos industriais em experiências visuais envolventes.

Como as instalações modernas apoiam o desenvolvimento e treinamento da força de trabalho?

As instalações contemporâneas de fabricação automotiva incluem centros de treinamento dedicados, parcerias educacionais e programas de aprendizado contínuo que preparam os trabalhadores para as demandas em evolução do setor. Esses espaços educacionais possuem sistemas avançados de simulação, equipamentos práticos de treinamento e ambientes colaborativos de aprendizagem que apoiam tanto o desenvolvimento individual quanto o avanço do setor, mantendo designs atraentes e funcionais.

Sumário

- Filosofia de Design Revolucionária na Fabricação Automotiva Moderna

- Práticas de Manufatura Sustentável e Inovação Ambiental

- Tecnologias Avançadas de Fabricação e Excelência na Produção

- Centros de Inovação e Instalações de Pesquisa

- Desenvolvimento da Força de Trabalho e Programas de Treinamento

-

Perguntas Frequentes

- O que torna as instalações modernas de manufatura automotiva diferentes das fábricas tradicionais?

- Como as práticas de sustentabilidade ambiental impactam o projeto e a operação das instalações?

- Qual é o papel da tecnologia na estética da fabricação automotiva moderna?

- Como as instalações modernas apoiam o desenvolvimento e treinamento da força de trabalho?